Superior Designed Features

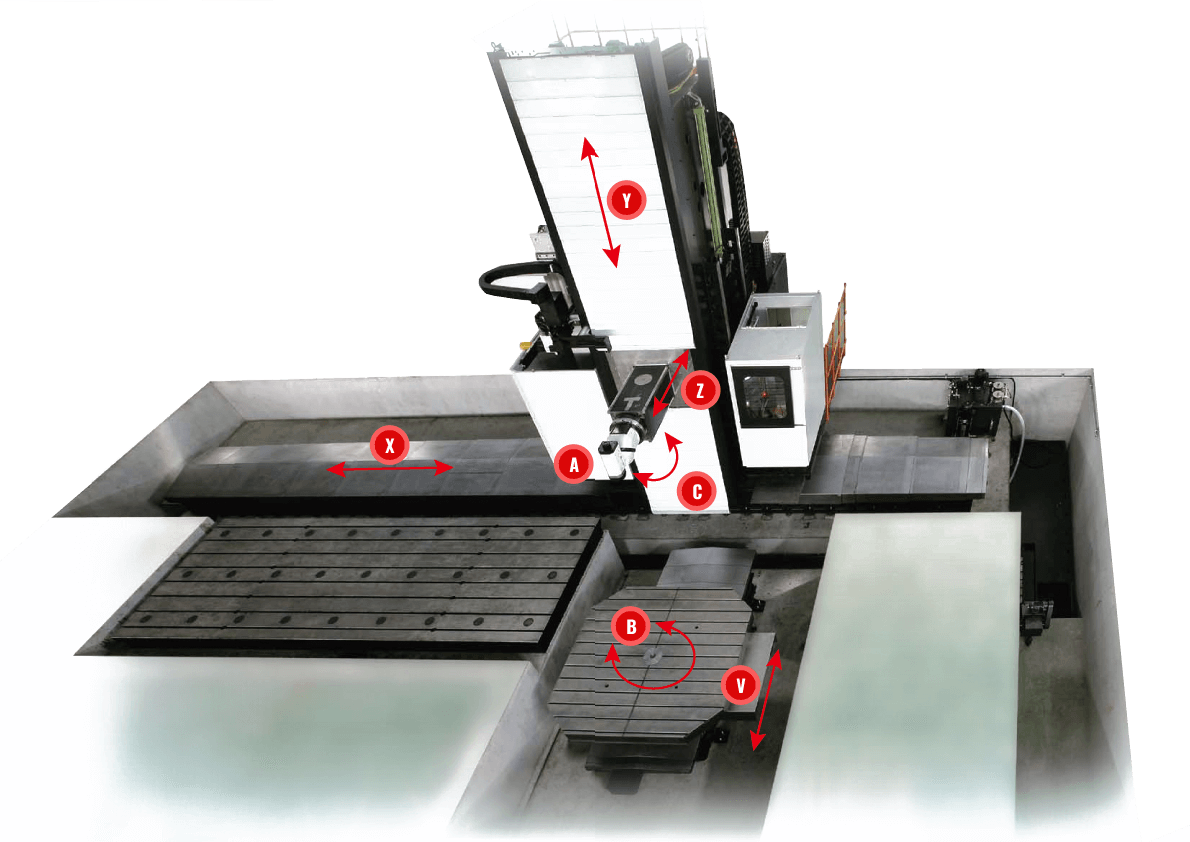

Machine shown in picture is 10 m(X) x 4 m(Y) x 1.3 m(Z) x ±180°(A) x ±360°(B) x ±360°(C) x 3 m (V) HSK-A100 / 12,000 RPM spindle, 60 ATC, 7 m x 2.5 m floor plate, Ø 2.5 m rotary table with 30 tons load, lifting operator cabinet.

High versatile due to wide range of machine configuration, besides standard Ø160 mm boring spindle such as various milling heads, floor plates, angle plates, rotary / rotary traveling / rotary traveling with tilting function tables, this is the most flexible machining center in the market, which is able to satisfy for the next decade various industries such as aerospace, energy ( wind power, gas, nuclear ), ship building, oil, rail way, mining and subcontractor machining sector etc. !

Range

- X4 m ~ 20 m, every 2 m modular

- Y2 m ~ 4 m, every 0.5 m modular

- Z1.2 m

- A± 180°

- Bup to 3 m rotary table

- C± 360°

- V1.5 m ~ 3 m, every 0.5 m modular

- W0.7 m or 1 m

4 Views of FBM-10040 Machine

- 10 m( X ) x 4 m( Y ) x 1.3 m( Z ) travel, 60 ATC, automatic lifting operating cabinet

- 7 m x 2.5 m x 350 mm floor plate & 2.5 m x 2.5 m B axis CNC rotary table with 30 tons load, 5 RPM and a 1,500 mm V axis travel. Fully CNC 2 axes universal milling head with 34 & 42kW HSK-A100 12,000 RPM spindle.

- 60 stations ATC, possibly change tools either vertical or horizontal or both.

- Operator and serviceman walking into machine directly from the back side of machine with easy access

FBM-4025

The twin ball screws & four roller guide ways on vertical sliding unit up & down in Y axis direction and then four roller guide ways for ram sliding forward & backward in Z axis direction, these maximum symmetric system ensures the very high rigidity and stiffness than any other competitors’ similar machine in this field, especially those last century designed traditional column side mounted & only two sides folded ram.

- 2.5 meter Y axis travel column

- 4 meter X axis travel bed

- FBM-4025 with 4 meter travel in longitudinal X axis, transmission by a rotating nut Ø80 mm high precision ball screw.

FBM-10040

- 4 meter Y axis travel column

- 10 meter X axis travel bed

Triple Boxes Designed – Box in Box in Box

- Triple boxes designed – Box in Box in Box, in addition, machine has been well FEA by using scientific development & technological research computer aided calculation of finite elements, machine has been well simulated & analysis with high accurate data, the stiffness, behavior and answers of the finished machine subjected to the highest stress and strains during the various machining phases.

- Ram balance system :The dynamic ram balance system, patented by Eumach, take care all the ram’s geometrical accuracy, straightness and parallelism:

- CNC control – by using servo motor and direct measuring linear scale, which check ram’s actual system response and make compensation of natural dropping ram.

- Balance system – this works in both positive & negative directions, it means that optimum compensation can be achieved for a wide variety of different head weights.

Triple Boxes Designed – Box in Box in Box

- X axis starts from 6 meter travel, all the Y axis travel and B axis rotary tables starts from 20 tons load machines are driven by two servo motors, two gearboxes and a double rack & pinion for X & B axis and two ball screws for Y axis. Such dual drives system with master slave control concept and nearly zero backlash advanced management allows a remarkable improvement of the stiffness and accuracy performance.

Various Milling Heads Available

Standard W axis boring spindle

Diameter Ø160 mm

Travel 700 mm

Speed 3,000 RPM

Power 37 & 45 kW (Fanucα40) or 37 & 51 kW ( Siemens1PH7167-2NF )

Torque See page 11

Optional Milling Heads

EXT

EXT90

HF50

VAR3

VH2.5

ORT

M21U

M21F

M21F with automatic head change

Various Optional Tables Available

Floor plate

Angle plate

Sliding table

Rotary table

Rotary & sliding table

Rotary & sliding & tilting table

Dimensions

Spindle Power & Torque

With Heidenhain or Siemens Control

With Fanuc Control

Specification

CNC Controls Available

FANUC

31i - MB

SIEMENS

840D

HEIDENHAIN

iTNC-530